All Products

-

Plastic CNC Machining

-

Metal CNC Machining

-

Low Volume CNC Machining

-

Vacuum Casting Prototype

-

Custom Sheet Metal Stamping

-

Prototype 3D Printing Service

-

Rapid Tooling

-

CNC Aluminium Extrusion

-

Automotive Rapid Prototyping

-

Medical Device Prototype

-

Smart Electronic Rapid Prototype

-

Mechanical Engineering Prototype

-

Aerospace Prototype

-

Home Appliance Prototype

-

Sports Device Prototype

-

Surface Finishing

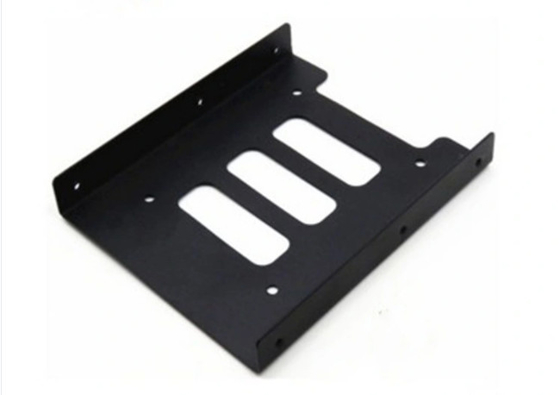

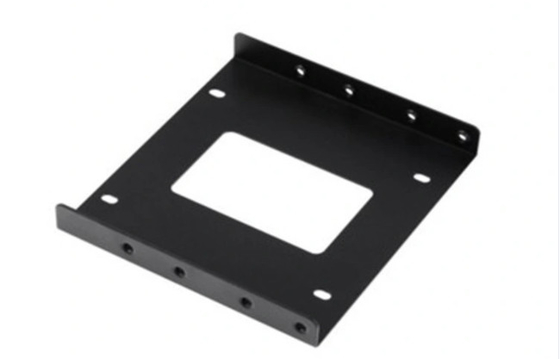

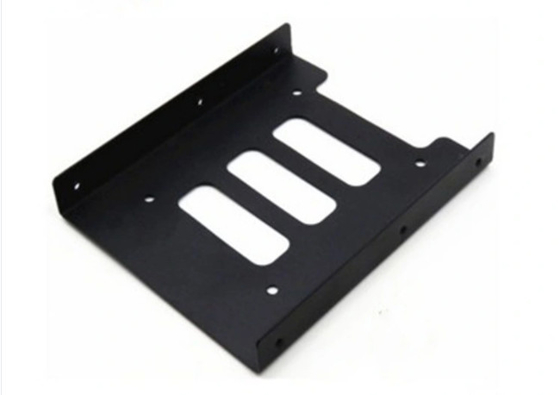

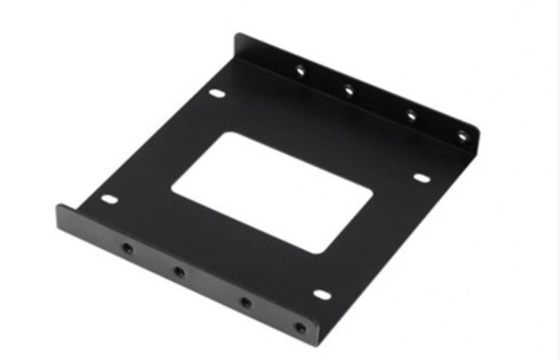

Bending Welding Sheet Metal Bending , Punching Steel Stamping Fabrication

| Place of Origin | China |

|---|---|

| Brand Name | Superior |

| Certification | ISO 9001,ISO27001 |

| Model Number | SPH-014 |

| Minimum Order Quantity | 1 |

| Price | USD+5+Sets |

| Packaging Details | Inner package: paper+ transparent plastic bag+foam outer packing: Carton/wooden/Customized one as client's request |

| Delivery Time | 3-7 Days for samples, 12-15 days for small batches |

| Payment Terms | T/T |

| Supply Ability | 1000000+PCS+per month |

Product Details

| Product Name | High Quality Custom Sheet Metal Bending Product Steel Stamping Fabrication | Process | Stamping/Bending/Punching/Welding Etc. |

|---|---|---|---|

| Service | Customized OEM | Color | Customized |

| Highlight | Welding Sheet Metal Bending,Bending Sheet Metal Bending,Punching Steel Stamping Fabrication |

||

Product Description

Product Description

1.0mm Metal Perforated Steel Plate Stainless Steel Sheet Metal

| A. Raw Material | Copper ,BeCu, phosphor copper, Brass, Stainless steel, Aluminum, SGCC, SECC, steel, spring steel, Nickel-Silver... and all different kinds of metal; |

| B. SPEC | Roll material thickness is 0.05-10mm;sheet metal thickness is 0.3-20mm; |

| C. Surface treatment | Gold / Silver /Tin / Nickel / Zinc / Chromium / Copper-plating / Laser etching/Screen printing/Phosphating (can pass salt spray testing with 160 hours)/Black coating / Painting/ Power coating /Electrophoresis / Passivating /Deburring / Polishing / Brush according to ROHS standard; |

| D. Application | All different kinds of telecom products, loom, furniture, and so on ; |

| E. Quotation | Please provide the Formal drawings (normally, with DWG/STP/PDF file ),and make note with material/QTY/surface treatment and any other requirements, we will provide you the quotation sheet in 48-72 hours; |

| F. Prototype & Mould | We make the prototypes or moulds according to the drawings that confirmed by both of us and customers! The lead time is depends on the structure and qty of parts, Normally, lead time for prototypes is 3-15 days; lead time for mould is 10-25 days; |

| G. Production | We will provide samples according to the drawings to customers for approval. Then arrange the production and confirm the delivery date according to the Purchase Order; Normally , the lead time for production is 5-30 days ,the structure of parts is different , the lead time will be different . |

| H. Package | Plastic bags; Preserving Box; Reel/tape package; Plastic tray; Wood box; Export carton and any other customized package according to the customers' requests. |

| Surface treatment | |

| Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated |

| Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing |

| Application | |||

|

Agricultural equipment

|

Computing equipment

|

Automobile industry

|

Textile equipment

|

|

Medical / dental instruments

|

Measuring instruments

|

Petrochemical industry

|

Safety equipment

|

|

Pharmaceutical industry

|

Pumps and general connections

|

Pharmaceutical industry

|

General machinery

|

|

Industrial valves

|

Fixing and movable equipment

|

Instrumentation equipment

|

Sanitary fittings

|

About Us

Recommended Products