All Products

-

Plastic CNC Machining

-

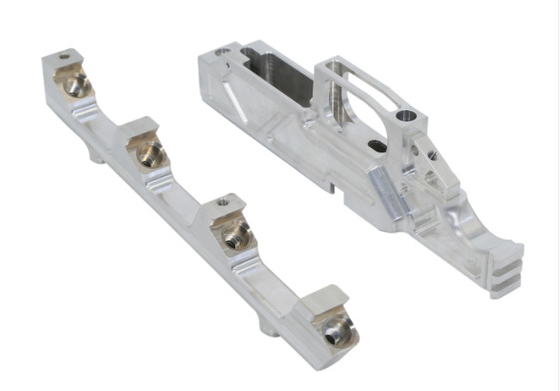

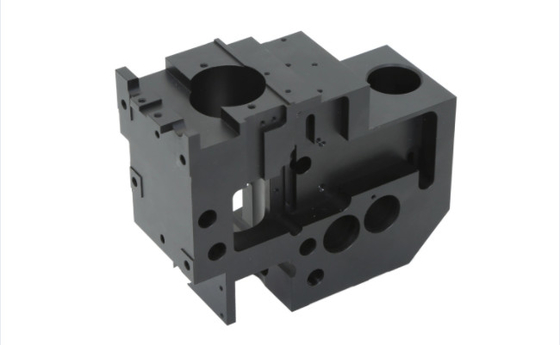

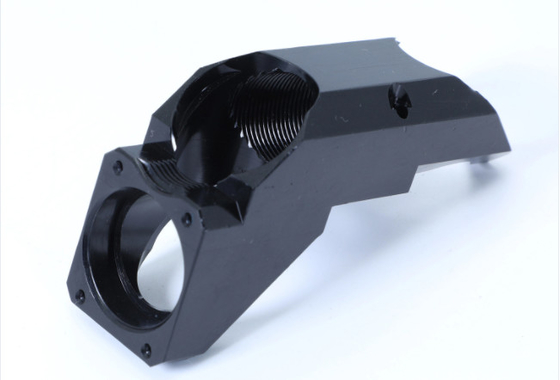

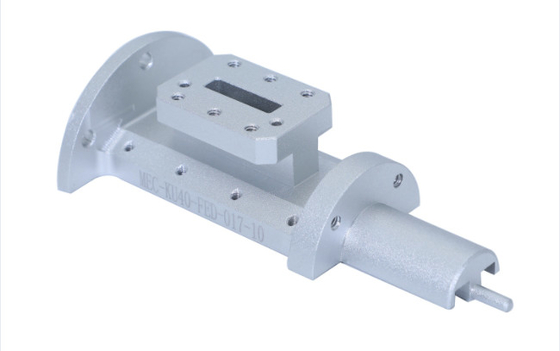

Metal CNC Machining

-

Low Volume CNC Machining

-

Vacuum Casting Prototype

-

Custom Sheet Metal Stamping

-

Prototype 3D Printing Service

-

Rapid Tooling

-

CNC Aluminium Extrusion

-

Automotive Rapid Prototyping

-

Medical Device Prototype

-

Smart Electronic Rapid Prototype

-

Mechanical Engineering Prototype

-

Aerospace Prototype

-

Home Appliance Prototype

-

Sports Device Prototype

-

Surface Finishing

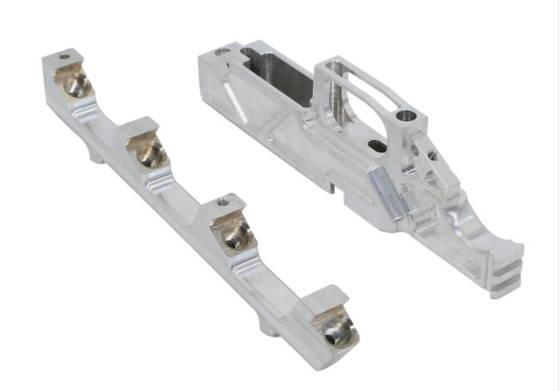

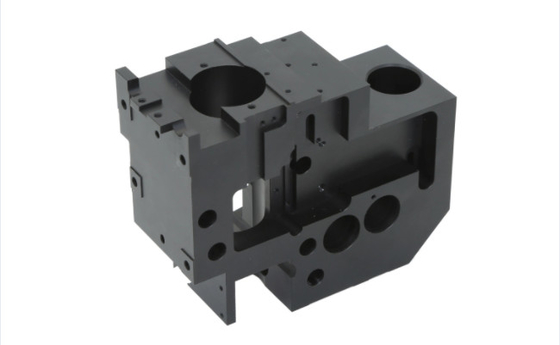

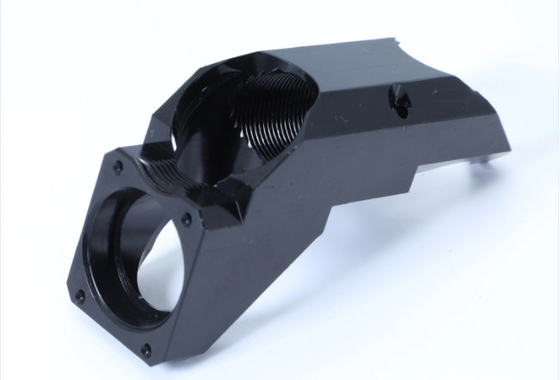

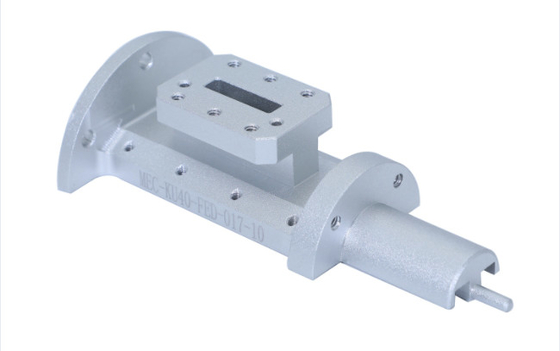

Precision Aluminum Brass CNC Turning Components 0.003mm

| Place of Origin | China |

|---|---|

| Brand Name | Superior |

| Certification | ISO 9001,ISO27001 |

| Model Number | SPH-018 |

| Minimum Order Quantity | 1 |

| Price | USD+5+Sets |

| Packaging Details | Inner package: paper+ transparent plastic bag+foam outer packing: Carton/wooden/Customized one as client's request |

| Delivery Time | 3-7 Days for samples, 12-15 days for small batches |

| Payment Terms | T/T |

| Supply Ability | 1000000+PCS+per month |

Product Details

| Product Name | Precision CNC Machining Part/CNC Turning Parts/Machinery Part/Aluminum Part/Brass Part/Medical Equipments | Quality Control | 100% Full Inspection |

|---|---|---|---|

| Lead Time | 5-7 For Samples | Production Capacity | 900 Million Pieces/Year |

| Highlight | Brass cnc turning components,Aluminum cnc turning components,Precision cnc turning parts |

||

Product Description

Product Description

1. Part Name:

Custom Design Precision CNC Machining Part/CNC Turning Parts/Machinery Part/Aluminum Part/Brass Part/Medical Equipments /Motorcycle Part/Auto Part Parts

Custom Design Precision CNC Machining Part/CNC Turning Parts/Machinery Part/Aluminum Part/Brass Part/Medical Equipments /Motorcycle Part/Auto Part Parts

| Process Technology | Workable size | Tolerance |

| CNC Turning | Φ0.5 - φ300 * 750 mm | +/-0.003 mm |

| CNC Milling | 510 * 1020 * 500 mm(max) | +/-0.01 mm |

| Drawing Format | IGS, STP, STL,X_T, DXF, DWG, PRO/E, PDF | |

| Test Equipment | Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |

| auge etc. |

3. Material Available:

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 etc. |

| Copper | C11000, C12000, C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP, PEI, Peek etc. |

3.Surface Treatment Available

| Zinc plating, Chrome plating, Nickel plating, Tin plating, Polishing, Anodizing, Power-coating, Oxide black, Sandblast Anodizing, Electroless nickel, Fe/Zn8/C PER ISO 2081, etc. |

4.Our Main Production & Inspection Equipments:

MARCHTON has 3, 4, and 5 axis CNC machining centers , CNC lathes, precision CNC milling machine, grinding machine, wire cutting, EDM machine, spectrometer, electronic altimeter, CMM etc. More than 50 sets of machine and testing equipment

| Application | |||

|

Agricultural equipment

|

Computing equipment

|

Automobile industry

|

Textile equipment

|

|

Medical / dental instruments

|

Measuring instruments

|

Petrochemical industry

|

Safety equipment

|

|

Pharmaceutical industry

|

Pumps and general connections

|

Pharmaceutical industry

|

General machinery

|

|

Industrial valves

|

Fixing and movable equipment

|

Instrumentation equipment

|

Sanitary fittings

|

About Us

Recommended Products