-

Plastic CNC Machining

-

Metal CNC Machining

-

Low Volume CNC Machining

-

Vacuum Casting Prototype

-

Custom Sheet Metal Stamping

-

Prototype 3D Printing Service

-

Rapid Tooling

-

CNC Aluminium Extrusion

-

Automotive Rapid Prototyping

-

Medical Device Prototype

-

Smart Electronic Rapid Prototype

-

Mechanical Engineering Prototype

-

Aerospace Prototype

-

Home Appliance Prototype

-

Sports Device Prototype

-

Surface Finishing

| Place of Origin | China |

|---|---|

| Brand Name | Superior |

| Certification | ISO 9001 |

| Model Number | OPQQ24020102 |

| Minimum Order Quantity | 1PCS |

| Price | US$ 0.1-100/Piece |

| Packaging Details | Inner package: paper+ transparent plastic bag+foam outer packing: Carton/wooden/Customized one as client's request |

| Delivery Time | 2-7 Work days |

| Payment Terms | T/T |

| Supply Ability | 800 Million Pieces/Year |

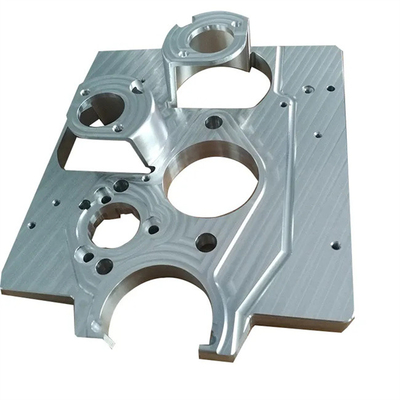

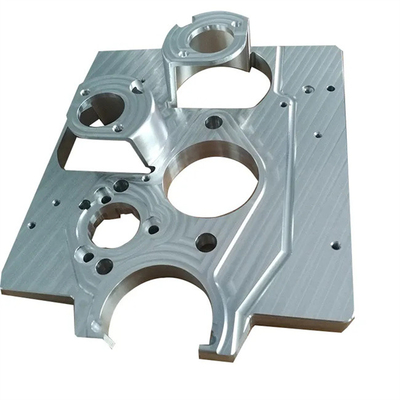

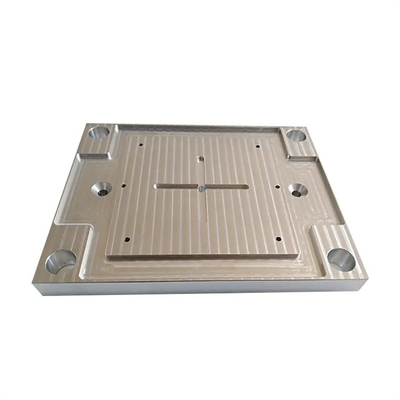

| Product Name | High Precision Aluminium Cnc Machining Parts Customized Metal For Rapid Prototyping | Technology | Cnc Machining |

|---|---|---|---|

| MOQ | 1pcs | Material | Stainless Steel,Steel,Aluminum,Brass,Copper |

| Application | Automotive, Medical Industry | Quality Control | 100% Inspention |

| Color | Original Aluminum Color/Customized | Surface Finsh | Polish,Anodizing, Nickel Plating, Zinc Plating, Electrophoresis |

| Highlight | Aluminium CNC Machining Parts,Customized Metal CNC Machining Parts,Rapid Prototyping CNC Machining Metal |

||

High Precision Aluminium Cnc Machining Parts Customized Metal For Rapid Prototyping

Type of technology:

CNC Machining is an automatic machine tool equipped with a program control system. It is an abbreviation of English Computerized Numerical Control, also known as numerical control machine tools, numerical control lathes. The control system can logically process and decode programs with control codes or other symbolic instructions, so as to make the machine move and process parts.

Advantage of CNC Machining technology:

1. High efficiency

CNC machining can realize automatic operation, reduce manual operation links, and can also achieve multi-axis linkage, efficient processing of complex surfaces and shapes, greatly improving production efficiency and processing quality.

2. High precision

CNC machining precision is very high, it can achieve micron level machining accuracy, thus ensuring the quality and stability of the workpiece.

3. Highly automated

Because CNC machining is digitally controlled processing, 24-hour uninterrupted processing operations can be achieved, thereby improving production efficiency and reducing production costs. In addition, CNC machining can also achieve automatic detection and identification of the workpiece through automated inspection technology, thus ensuring the quality and stability of the workpiece.

4. Programmability

CNC machining can be controlled by computer programming, so that different machining operations can be realized. This allows CNC machining to have a very high degree of flexibility and adaptability, while also guaranteeing machining quality and precision.

5. High reliability

Because CNC machining is digitally controlled processing, it will not be affected by human factors, thus avoiding the occurrence of failures. In addition, CNC machining can also realize the monitoring and maintenance of the machine tool through automated inspection technology, thus ensuring the stability and reliability of the machine tool.

Information:

|

Product Name

|

High precision aluminium cnc machining parts customized metal for rapid prototyping

|

|

Type of technology

|

CNC Machining |

|

Industry

|

Automotive, Medical Industry

|

|

Material

|

Stainless Steel,Steel,Aluminum,Brass,Copper

|

| Color | Stainless Steel,Steel,Aluminum,Brass,Copper |

| Surface finish | Polish,Anodizing, nickel plating, zinc plating, electrophoresis |

| Tolerance | ±0.05mm/ ISO 2768-M |

![]()

![]()

![]()

![]()

![]()

![]()

About Superior:

Superior Prototype Co.,Ltd was established in 2006 which is a high-tech enterprises professional to Plastic, Metal prototype and Small batch production such as Vacuum Casting and Stamping Sheet Metal. Our company covers an area of 15,000 square meters, has 400 employees which including about 170 technical staff (RD. QE, CNC,Engineer) .

With the development of the business growth, we have imported Die cuting, Stamping, Sheet metal NCT, 4 and 5 Axis CNC Machine etc., So we can provide one-stop service of rapid prototype.

|

Optional

|

CNC Machining/Sheet Metal/3D Printing/Vacuum Casting/Lathe/Fast Mould etc.

|

|

Material

|

Aluminum, Nylon, PP, ABS, PMMA, PC, POM, Steel, Iron, Alloy Metal, SGCC, SECC, SPCC etc.

|

|

Size

|

Customized Size. Appointed size to match the products.

|

|

Design and Advise

|

Design and skilled support, put your good ideal into reality.

|

| Inspection | 1. 100% inspection on critical dimension; 100% on appearance. 2. Third Party inspection available upon requirement |

| After-sales Services | Video Techincal Support, Online Support, Engineers. |

|

Sample Cost

|

Free of sample cost. Normally is USD 35~110 per style. If special design we need sample charge. We can refund when have official bulk order.

|

|

Sample time

|

Common products 1-7 days after received drawing and payment.

|

|

Delivery Time

|

1-25 days after order with prepayment based on products structure and quantity.

|

|

Payment Terms

|

Only 30% Deposit.(Make your floating capital more effective.)

|

|

Shipping

|

By Air or Sea.(If Choose by Air, it is Faster Like You Purchase from Local Market.)

|

|

Quality Guarantee

|

5 years(Depends on specific products) |

|

Service Type

|

OEM/ODM

|

Our Certificate:

![]()

![]()

Our Products:

![]()

Surface Finish:

![]()

Exhibition:

![]()